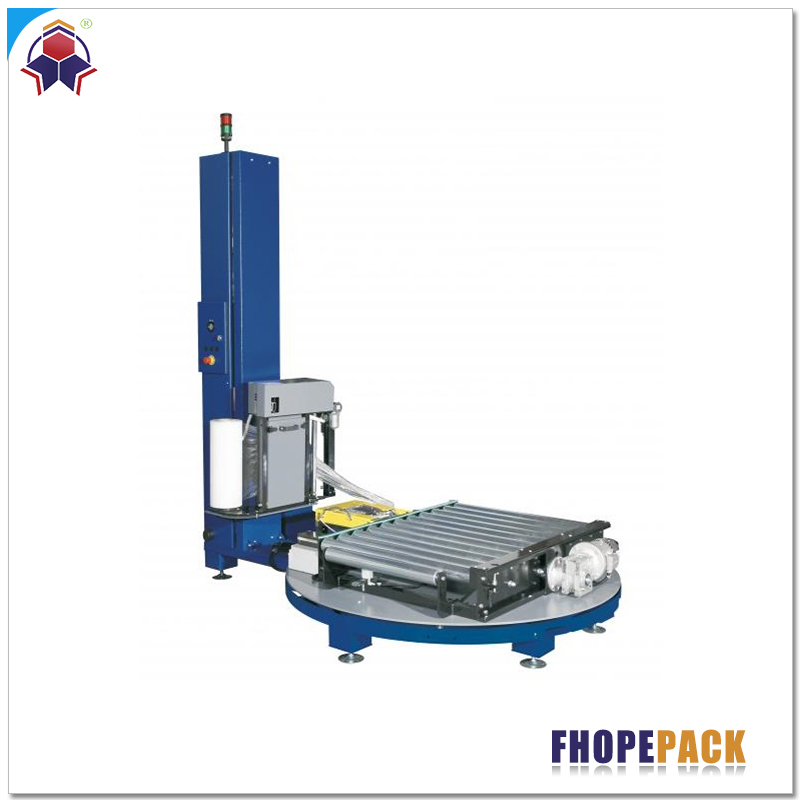

stretch wrappers

http://ww.fhopepack.com/blog/semiauto-orbital-stretch-wrapper-video/The packaging features have been narrowed down, which will make the biggest economic difference in your loading zone, whether you pack 50 times a day or pack 500 times. In the long run, there are many functions that can be saved, and even in many cases, it is possible to pay for the entire machine in less than a few years. Here are some ideas to help you visualize which functions actually increase efficiency. In the first five years, simple automation saved the average customer a lot of labor, and we could see at least $50, 000 in labor. At the end, the thin film is cut off by fpc2, which can be connected to the load at the beginning of the loop. This means that your operator can still stay on the forklift, and it is ok to use remote control to start the machine. Now he can perform another task, and the load package (for example: take another load, print the shipping tag, and complete the bill. Transportation losses can be prevented by a loader’s connective device, and companies lose a lot of money each year, which can be as much as billions of dollars. About $30,000 could be saved by this device for the average customer – otherwise the load off the tray would be lost – on the stretch package of economic life. A thin film applied to the top of your tray is a special roller, and between the load and the pallet, a strong connection needs to be established. If there is no proper load to the pallet connection, you risk a great deal, such as the risk of slipping off the tray during transit, and it will be damaged. They may disintegrate or occur with a nearby load collision.