You can keep your stretcher like new, at runtime.

This is the beginning of the New Year. Many of us have made up our minds to organize, they want to eat healthily and spend more wisely.

The thing you need to do is keep your semi-automatic stretching packaging equipment healthy, so that your work budget can be extended.

When the stretch wrapper is involved, you can do some simple things, low cost and no cost objective is to ensure that your machine is working well, at the same time, the load for you, it can also be packaged as possible.

Here are some common problems and trouble spots:

First, there are squeaks, grinds and pimples.

If the machine is not properly set, it will cause unnecessary wear. If the machine is working properly, a noticeable noise or vibration will not appear. Second, the mobile component bindings

Periodically. The part that gets stuck is the ability to stop stretching the wrappers. Once again, the machine should be able to run smoothly, and there is no obvious noise or movement shock.

Third, project tracking and wearing

There should be no barriers, tears, or abrasions to the movie delivery and dial/winding armband.

Fourth, loose or missing hardware.

Because of the loose components, unnecessary wear and tear is caused, so we all know that the very danger is the loss of parts.

Do you know what other areas to check? It includes cracks or broken guards, film necks and debris.

Most of these problems can be solved by yourself. However, there is a problem that you may encounter, and to be honest, it is a little serious. If that happens, don’t hesitate to call the certified technician and ask them to check.

Simple preventative maintenance can not only extend the lifespan of your stretched wrapping, but also allow you to put your money in your pocket in the days to come.

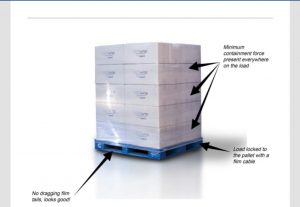

Are you looking for other ways to improve? You can check our 10-step process and you can reduce the damage by stretching the packaging more effectively. Our process will show you a lot of things: 50% of the transportation costs will be reduced. Key elements of the tensile packaging standard can also be displayed. How do you manage the containment? The most critical component of stretching is the containment force.