The size of the film has been reduced or pre-stretched has increased impact on package force, control, throughput and film costs.

We all know that stretching is an economic measure, or, more accurately, that it is an economic measure to stretch a film before it is released. A stretch film that can be affordable is the pre-tensioning membrane, and the stretch film and stretch film industry we know today are also opened.

The pre-tensioning film can achieve the goal of saving money.

In 100% of pre-stretching, for example, has carried on the increase of the 6000 – foot – long film, into a 12000 feet, in the top 200% of the tensile, the same 6000 feet of film has changed, become 18000 feet, and so on.

In most stretch packs, pre-stretching is standard. According to their configuration, pre-stretching between 100 and 300% of the movie can be done. However, between 200 and 250% is the proportion of most companies. This has been achieved with good balance between economy and efficiency.

In the absence of pre-stretching, an average customer would need to be used for 50 times over five years, and about $35,000 of film was wasted. Although your car may not pay for themselves within two years is what we all know, however, for many companies, if it is a has a pre-stretching fpc1 stretch wrapper, in less than two years’ time, you can pay for the movie alone.

What is the best way to determine best picture usage? Such as:

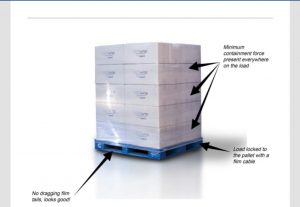

Load criteria need to be built: they include control values, load to pallet keys, not long or drag-down film backs. They maximize the possibility of safe shipment. We can determine Settings: the quality, specifications, the prices are the choice of film, the adjustment of the machine, the pre-tension percentage, parcel force, at the top and bottom of the package count, film transfer system speed up and down, the film overlap, and so on all need to be adjusted, ensure that reach the standard is our goal.