If you want to improve the quality of the stretch film itself, thickness and complexity, will lead to the increased cost of membrane, if used to achieve the desired control membrane layer is reduced, so as to realize the increase of production, so we can see that the film cost should be not bad.

We all know that each situation is different, so it is essential to make the right recommendations in terms of the professional knowledge and experience of the film and the stretching package.

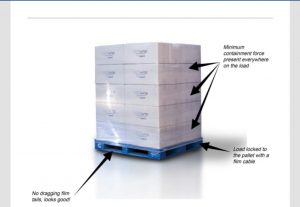

Third, the effect of membrane rupture on package force and restraining force.

We’re talking about this problem, or we can call it confusion, usually in the face of film selection. The movie is sold at the price of each volume. Generally, an inclusive component is not included. Therefore, customers find that it is very rare to rationalize between film price and control specification. A medium size film user is our sales manager to see, so you can see he is now in the hard struggle, in several high quality film brand and’s pursuit of struggle in the process of their distributors. He chose the lowest number of suppliers (which, in his opinion, is a good movie). But with the production of movies and movies, it’s slowly proved that this is a bad choice, and it’s not easy to get the movie break. When a containment forces is he considered to use contain power as his specifications and price of each roll, we can take an examination of university “the weight of the world” was released from his shoulder, he felt that he now has a real car, the car to compare different films, and he made a wise decision.

And don’t forget about other considerations. We know that in high-speed packaging applications, frustrating and expensive downtime can be created by overstretching the membrane. In irregular loads (such as distribution centers) and load angles, this is particularly common if the method is not adjusted by the machine.